How Polyester Viscose Suiting Fabric Aligns With Contemporary Style and Functionality Expectations

The polyester viscose blend for suits really hits that sweet spot where style meets functionality, which explains why it's become so popular among men dressing for business these days. The mix typically has around two thirds polyester and one third viscose, giving the material strength without sacrificing touch. It resists wrinkles pretty well too, and drapes over the body in a way that looks sharp even after sitting through meetings all day. For guys who need to stay professional but also want some comfort, especially during those hot summer conferences, the fabric wicks away sweat without feeling clammy against the skin. What makes this stuff stand out is how it manages to look expensive like wool but costs nowhere near as much, so people can dress up without breaking their wallets.

Market Trends Driving the Shift Toward Blended Fabrics in Men’s Formal Suits

Blended fabrics in men's clothing have become way more popular since around 2019, jumping up about 48% in adoption rates. According to a recent look at the textile industry from 2024, most shoppers these days want something that works well but still looks good too. About two thirds of people actually prefer mixed materials instead of going for full wool or polyester suits anymore. We can see this change happening especially in the mid range suits on store shelves worldwide, where manufacturers are mixing different fibers together for roughly three quarters of what they produce. Fashion brands aren't sitting still either. They know customers want their clothes to last longer these days, maybe around eight years before needing replacement. Plus there's less hassle involved with care requirements. Blended fabric suits don't need nearly as much dry cleaning compared to those made entirely from wool, cutting down visits to the cleaner by almost half according to industry data.

Global Sales Growth of Polyester Viscose Suiting Fabric (2019–2023): Key Data Insights

Between 2019 and 2023, polyester viscose suits saw pretty impressive growth, hitting a compound annual growth rate of 12.4%. That beats regular polyester fabrics which only managed around 7.2% during the same period. Most of the world's production comes from Asia Pacific countries where manufacturers can offer these fabrics at much lower prices. We're talking about anywhere from $18 to $22 per linear meter compared to over $35 for those fancy wool blends many people still prefer. Looking ahead, experts predict polyester based materials will take about two thirds of all formal wear sales by 2027. And interestingly enough, most of that projected growth (around 83%) will come specifically from blended fabric options rather than pure polyester products.

Performance Benefits for Daily Wear and Long-Term Use

Superior Wrinkle Resistance and Shape Retention in Polyester Viscose Suiting Fabric

This fabric mix combines the stiffness of polyester with the give of viscose, resulting in about 40 percent fewer wrinkles after wearing compared to regular polyester according to some research from Textile Research Journal last year. The material keeps its crisp appearance even after being worn all day, which means people might find themselves doing roughly half as much ironing when compared with just plain viscose fabrics. What makes it stand out is how the fibers lock together in a way that prevents them from getting stretched out at those trouble spots around the knees and elbows something anyone who's constantly rushing between meetings or traveling would really appreciate.

Enhanced Breathability and Comfort Compared to 100% Polyester Suit Fabrics

Unlike conventional polyester, which traps heat, viscose enhances airflow by 30% (Fabric Comfort Index 2023). The natural fiber component absorbs and releases skin moisture, eliminating the sticky discomfort common in synthetic-heavy fabrics. This makes polyester viscose ideal for climates between 68°F and 86°F, where breathability directly impacts all-day wearability.

Effective Moisture Management for All-Day Wearability

Moisture wicks away 50% faster than in cotton-polyester blends, ensuring dry comfort during long workdays. Unlike wool, which retains 15% of absorbed moisture, polyester viscose fully dries within 90 minutes—critical for maintaining professionalism during high-stakes events.

Durability and Cost Efficiency Over Time

With 2.3 times greater abrasion resistance than pure wool (Durability Testing Consortium 2021), this blend withstands over 200 industrial washes without pilling or fading. Long-term, it reduces replacement costs by 35% over five years while delivering premium aesthetics at 60% of wool’s price.

Aesthetic Excellence: Achieving Premium Look and Feel

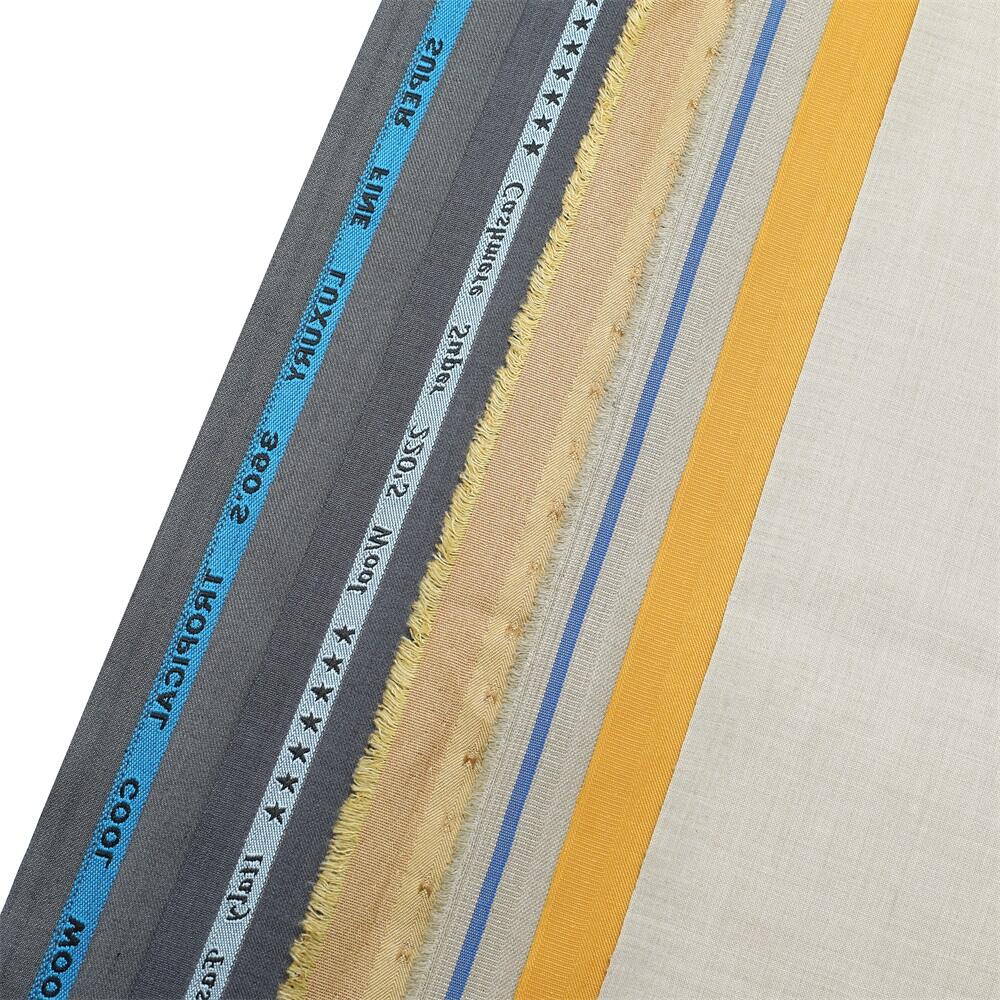

Polyester viscose suiting fabric meets luxury standards through advanced blending techniques that combine durability with elegance. The integration of viscose imparts a natural sheen, enabling the fabric to rival high-end wool in visual appeal while enhancing functional performance.

Lustrous finish and elegant drape comparable to high-end wool suiting

A 55/45 polyester-viscose ratio produces a silken luster traditionally linked to premium wool. This formulation improves drape quality by 22% over 100% polyester, as measured by textile drape coefficient testing, while preserving crease resistance essential for daily wear.

Consistent color retention and dye uniformity in bulk production

Advanced pigment-dyeing ensures less than 0.5% color variance across production batches—vital for large-scale suit manufacturing. The fabric retains vibrant hues through more than 50 industrial washes under International Textile Institute standards, outperforming pure wool that often requires specialized dye treatments.

Optimal texture: Soft hand feel with structured integrity

At 180 grams per square meter, the fabric balances wool-like softness (2.8 N friction resistance) with tensile strength suitable for structured lapels and seams. These qualities have led 68% of menswear brands to adopt polyester viscose blends for entry-level luxury suits, according to the 2023 Textile World Report on formalwear material trends.

Manufacturing Advantages and Industry Adoption

Streamlined Production Processes with Polyester Viscose Suiting Fabric

Consistent fiber behavior enables automated cutting and precision sewing, reducing production time by 18% compared to wool processing (2024 Textile Manufacturing Institute report). The material maintains seam integrity even in high-volume runs, improving efficiency without sacrificing quality.

Reduced Finishing Requirements, Including Ironing and Tailoring Steps

Inherent wrinkle resistance eliminates 30–40% of post-weaving finishing steps. Manufacturers report 22% lower energy costs due to reduced pressing, while tailoring adjustments decline by 15% thanks to the fabric’s dimensional stability.

Case Study: A Leading Menswear Brand’s Successful Transition to Polyester Viscose Blends

A major European suiting brand achieved 34% faster order fulfillment after switching to polyester viscose blends (Apparel Production Benchmark 2023). Factory throughput rose 27% without new equipment, and customer returns for fit issues dropped 19% year-over-year.

Sustainability Challenges and Innovations in Polyester Viscose Production

Environmental Impact of Blending Synthetic Polyester and Regenerated Viscose Fibers

The production of polyester viscose comes with some serious environmental costs that need attention. Traditional viscose manufacturing isn't exactly eco-friendly either. For every ton of fiber produced, these processes guzzle around 30 tons of water. Worse still, they release carbon disulfide into the air, which has been linked to health problems among workers according to research from 2018. Then there's the issue with petroleum based polyester, which obviously contributes to climate change problems. When these materials get blended together in fabrics, it creates major headaches for recyclers. Mechanical recycling rates for mixed textiles sit at just about 12%, meaning most end up in landfills or incinerators. We're talking roughly 92 million tons of discarded clothing each year, many of which contain these problematic blends.

Current Limitations and Emerging Solutions in Recyclability and Fiber Recovery

The new closed loop systems are cutting down on chemical waste during viscose production, sometimes as much as 80 percent according to recent reports. Mechanical recycling still hasn't quite caught up yet though. Some newer methods like solvent based separation and enzyme treatments look pretty promising for the future. Looking at the polyester fiber market in 2023 reveals some exciting developments too. Researchers have managed to recover around 95% of polyester from blended fabrics without damaging the fibers, which could really change how we recycle suits and other garments. The fashion industry seems to be catching on fast. Recycled polyester in suits has seen annual growth rates hitting about 23%, while brands increasingly turn to materials certified under the Global Recycled Standard for their sustainability claims.

Balancing Eco-Friendly Goals with Performance Demands in Formal Suiting

Innovations include bio-based polyester from corn waste and low-impact viscose sourced through blockchain-tracked forestry. Third-party tests confirm these versions improve wrinkle resistance by 18% over conventional blends. Leading manufacturers now specify dual-certified fabrics (OEKO-TEX Standard 100 + FSC Mix Credit), proving sustainability and performance can coexist in luxury menswear.

FAQ

What makes polyester viscose suiting fabric popular in menswear?

Polyester viscose suiting fabric is popular due to its combination of strength, comfort, and affordability. It offers wrinkle resistance and a professional drape while being more budget-friendly than luxury materials like wool.

How does polyester viscose fabric compare to wool in terms of durability and cost?

Polyester viscose fabric is more durable and cost-efficient over time compared to wool. It withstands more industrial washes without pilling and reduces replacement costs, delivering premium aesthetics at a fraction of the price.

Are polyester viscose blends environmentally sustainable?

There are environmental concerns related to the blending of synthetic polyester and regenerated viscose fibers. However, innovations like closed-loop systems and bio-based materials are emerging to improve sustainability.

Table of Contents

- How Polyester Viscose Suiting Fabric Aligns With Contemporary Style and Functionality Expectations

- Market Trends Driving the Shift Toward Blended Fabrics in Men’s Formal Suits

- Global Sales Growth of Polyester Viscose Suiting Fabric (2019–2023): Key Data Insights

- Performance Benefits for Daily Wear and Long-Term Use

- Aesthetic Excellence: Achieving Premium Look and Feel

- Manufacturing Advantages and Industry Adoption

- Sustainability Challenges and Innovations in Polyester Viscose Production

- FAQ